A Client’s Testimonial: Exceptional Service, Excellent Results.

The following testimonial is from a leader operating a specialty chemical production facility. For over a year, Avid’s team has served as their process control and automation support team. “I am writing to express my enthusiastic support and recommendation for Avid. Having had the pleasure of collaborating with Avid on multiple projects over the past […]

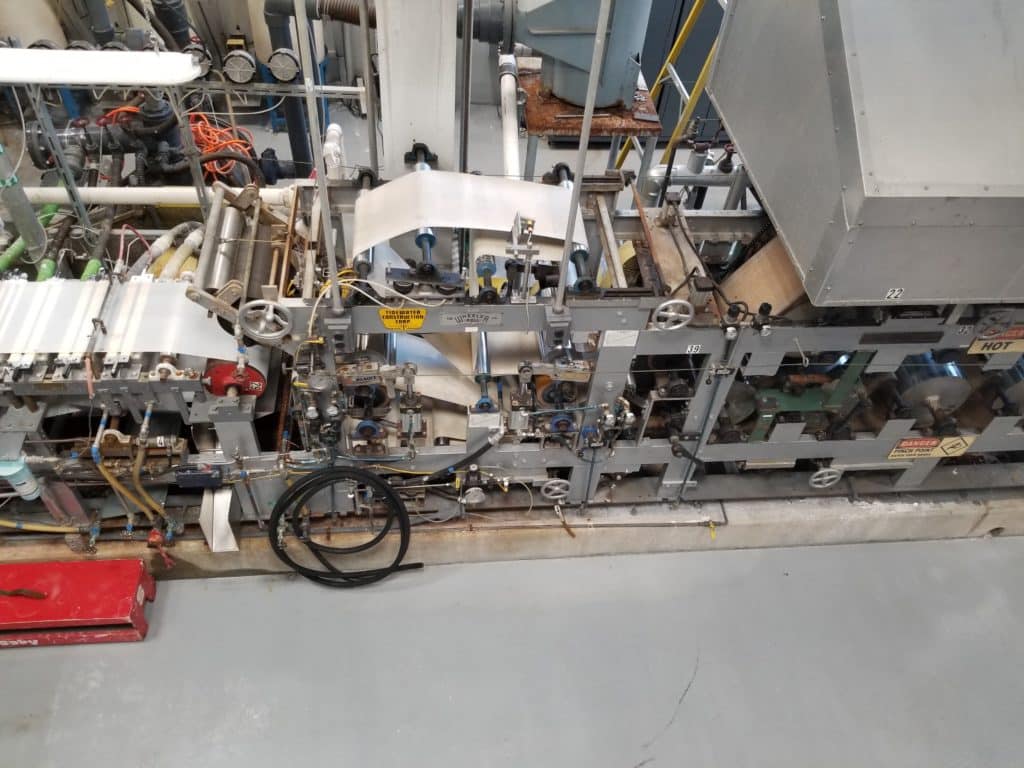

Avid Solutions Upgrades a Pilot Paper Plant

At North Carolina State University, a paper production pilot plant is operated for research and education relating to the pulp and paper industry. This represents a unique real-world opportunity for testing and investigation by their students, staff, and industry partners. When it came time to upgrade the legacy controls, a joint project was initiated with […]

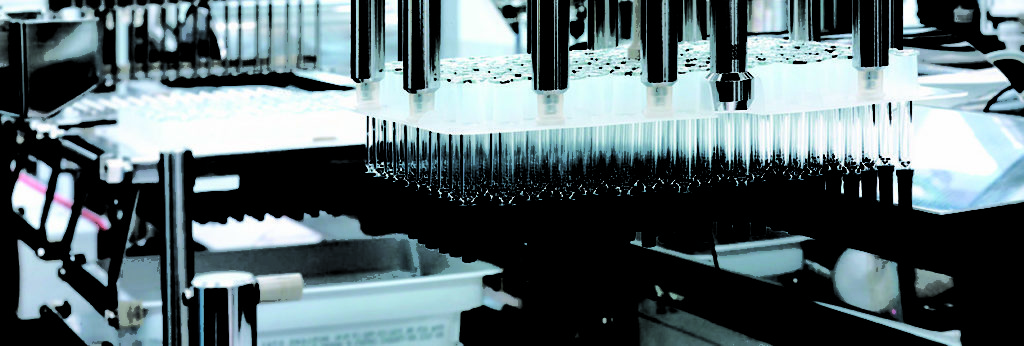

Data Integrity for a Biopharma Business? It’s only Logical!

A clinical-stage biopharmaceutical client needed a solution for ensuring the Logical Integrity of their skid-based data. The Process: After examining the current data collection process and database structure, it was determined that the client did not have a consistent way to extract the data into reports for more valuable analysis and understanding of their batch […]

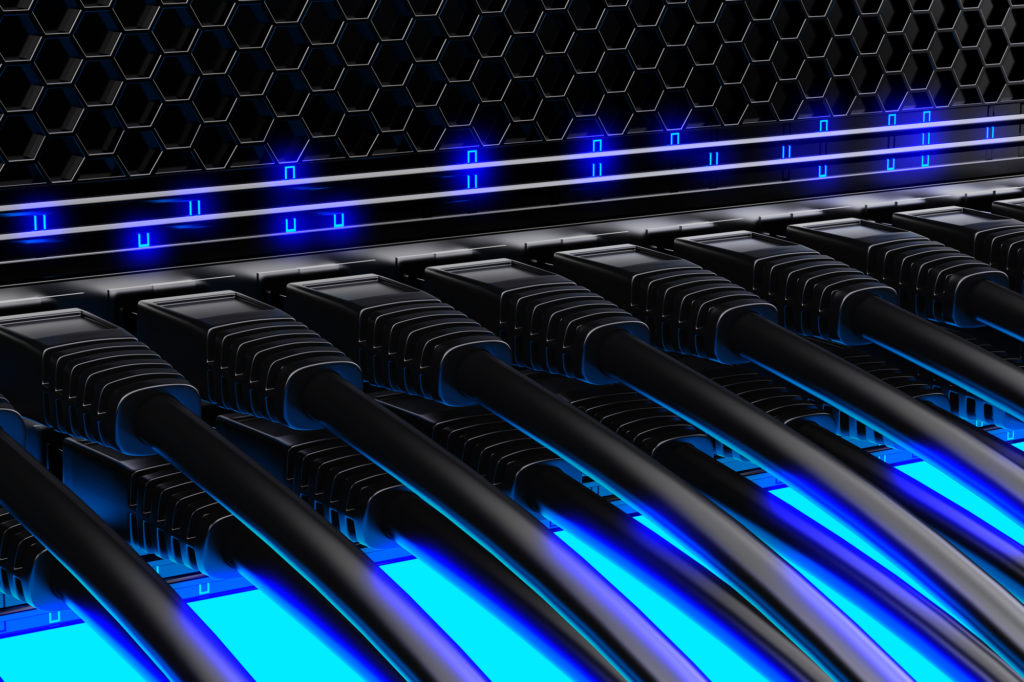

Expert Data Integration: Made Easy by Avid!

Accessing data from all process system are critical to optimizing performance. Production, quality, health and safety, and environmental compliance all count on accurate data. Avid’s team of control system and networking experts, make connecting systems easy! A recent example of our capabilities involved a provider of healthcare products. This producer called on Avid to upgrade […]

Very Cool: Avid Expertly Delivered A Solid Solution!

A world-class producer of IV & Irrigation Solutions selected Avid Solutions to design and install a process control system for a new cooling tower unit. The new unit is designed to provide a steady supply of chilled water. As a result, this unit now enables the producer to stabilize and sustain the supply of chilled […]

Saved! Avid Delivers a Robust Disaster Recovery Solution

Customer Profile: A pharmaceutical plant producing anti-infective treatments against serious and often life-threatening infections. Background: The client’s facility experienced a power failure. It started on a weekend resulting in the control systems being unresponsive. Log files showed that the systems did not recover. When one of the three servers would not respond […]

Failed Data Integrity Audits are Painful. Avid can Help!

Background Our client, a multi-billion-dollar specialty pharmaceutical company, has been providing high-quality products to a large portfolio for over 150 years. They observed a steady decline in production levels and were looking to their historized data to diagnose the issue. However, they quickly realized that they only had 90 days of historized data. This duration […]

Greenfield site for Oncology medicines

Context: Greenfield site for Oncology medicines in a parenteral format supporting commercial and clinical operations Pain: New facility with new staff and new unit operations. Getting production up and running in a timely manner while minimizing the possibilities for human error based on inattention to detail or inexperience with the process. Solution: An integrated platform […]

A Tin Plating System That’s Worth It’s Weight in Gold

Avid Solutions takes an outdated, underperforming electroplating system and turns it into an efficient, state-of-the-art, well-oiled machine that will stand the test of time. Background The client is a full-service fabrication, machining and electroplating operation that has been providing finished components to a wide range of manufacturers since 1986. They were long overdue for an […]

Outcome-Based Engineering Case Study

The Optimization of Evaporators Background Our client was coping with a daunting combination of performance issues with their multiple evaporators: throughput issues, energy costs, and product quality. In response, we completed an Outcome-Based Engineering (OBE) field study of an evaporator and determined several operational improvement opportunities. The OBE study determined that adding instrumentation, a variable […]