Saved! Avid Delivers a Robust Disaster Recovery Solution

Customer Profile: A pharmaceutical plant producing anti-infective treatments against serious and often life-threatening infections. Background: The client’s facility experienced a power failure. It started on a weekend resulting in the control systems being unresponsive. Log files showed that the systems did not recover. When one of the three servers would not respond […]

Secure Operation! A Control System with Fail-Safe Backup

Creating and implementing a batch system that operators can run manually if the batch system is unavailableBackground Avid gets a lot of these requests! A producer of specialty chemicals contacted Avid to design and deliver an Emerson Delta V control system. This system needed to provide automated batch processing capabilities. The challenge was to design […]

Failed Data Integrity Audits are Painful. Avid can Help!

Background Our client, a multi-billion-dollar specialty pharmaceutical company, has been providing high-quality products to a large portfolio for over 150 years. They observed a steady decline in production levels and were looking to their historized data to diagnose the issue. However, they quickly realized that they only had 90 days of historized data. This duration […]

Greenfield site for Oncology medicines

Context: Greenfield site for Oncology medicines in a parenteral format supporting commercial and clinical operations Pain: New facility with new staff and new unit operations. Getting production up and running in a timely manner while minimizing the possibilities for human error based on inattention to detail or inexperience with the process. Solution: An integrated platform […]

A Tin Plating System That’s Worth It’s Weight in Gold

Avid Solutions takes an outdated, underperforming electroplating system and turns it into an efficient, state-of-the-art, well-oiled machine that will stand the test of time. Background The client is a full-service fabrication, machining and electroplating operation that has been providing finished components to a wide range of manufacturers since 1986. They were long overdue for an […]

Outcome-Based Engineering Case Study

The Optimization of Evaporators Background Our client was coping with a daunting combination of performance issues with their multiple evaporators: throughput issues, energy costs, and product quality. In response, we completed an Outcome-Based Engineering (OBE) field study of an evaporator and determined several operational improvement opportunities. The OBE study determined that adding instrumentation, a variable […]

From Archaic to Automated – Without Missing a Batch or a Beat

Avid Solutions transforms a specialty batch chemical company’s production process from manual to fully automated. Background The client is a leading specialty chemical company with a presence in more than 25 countries throughout the world. The company’s core business is the development, manufacturing and marketing of plastics, rubber, intermediates and specialty chemicals. A portfolio of […]

Developing an integrated tracking and control system for a new drug manufacturing plant.

Background A major pharmaceutical company built a facility in Research Triangle Park, NC to manufacture and package a new cancer drug. The drug is produced from a highly potent compound on an aseptic filling line using isolator technology. Avid Solutions was given the job of implementing a control system to track and coordinate all the […]

SCADA Implementation for New Aseptic Fill Line

Client Profile A major pharmaceutical company enlisted Avid Solutions to help install a new Aseptic Fill line in their primary Fill / Finish facility. Being that the project was to be executed in an operating site, Avid faced numerous challenges, including the necessity to minimize production downtime. ChallengeA key element of the project was the […]

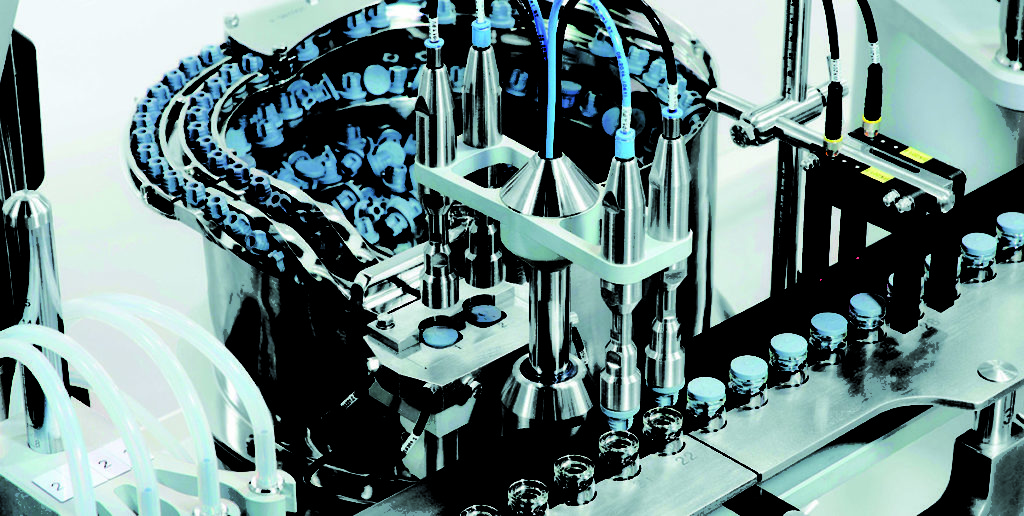

Aseptic Production Facility Capacity Expansion

Customer Profile: Integrated Automation for Batch Process / SCADA / PLC Control System(s)(Aseptic Formulation, Sterile Storage, Aseptic Filling and Clean Utilities) Background A major pharmaceutical company in NC expanded their manufacturing capacity by adding a new production line, thereby greatly increasing the production volume of one of their critical medications. This new line capacity expansion […]