Case Study

Context: Greenfield site for Oncology medicines in a parenteral format supporting commercial and clinical operations

Pain: New facility with new staff and new unit operations. Getting production up and running in a timely manner while minimizing the possibilities for human error based on inattention to detail or inexperience with the process.

Solution: An integrated platform capable of batch execution with bidirectional data flow from the ERP to the production automation systems. A combination of direct control and detailed interfaces with vendor equipment ensured that operators were always executing the right step at the right time and all data was properly recorded with context to allow for extensive electronic batch reports at conclusion of the process.

Impact: A system that provides a uniform interface for operations and engineering to monitor, maintain, and execute critical functions throughout the facility

Select Client List

- Biogen

- Grifols

- Novo Nordisk

- Pfizer

- United Therapeutics

- Xellia

Avid can consult, engineer, and integrate these operations activities to help you meet and exceed your production KPIs

- Process Management

- Performance Analysis

- Dispatching production units

- Maintenance Management

- Operations Scheduling

- Quality Management

- Document Control

- Product Tracking & Genealogy

- Labor Management

- Data Collection

- Resource Allocation & Status

As a life sciences manufacturer, your manufacturing systems are an important link in achieving and maintaining your competitive advantage. With the rapid evolution of automation and manufacturing execution systems, end-users are often challenged to find the best fit for their unique processes.

Avid is the ideal partner to help you navigate the technology selection, engineering, and delivery to help you achieve your desired outcomes. Whether you’re making greenfield CAPEX investment or seeking to maximize the ROI from your OPEX spend, trust us to ensure you have the technology you need to meet your goals.

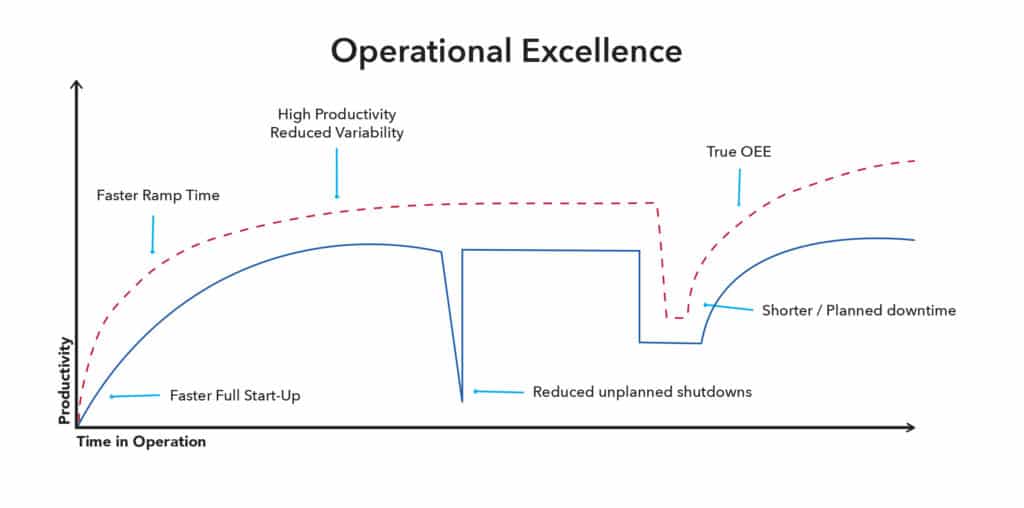

From unplanned downtimes, inefficient asset utilization, and unsecure systems to continuous, efficient, and secure.

Run Better.