At North Carolina State University, a paper production pilot plant is operated for research and education relating to the pulp and paper industry. This represents a unique real-world opportunity for testing and investigation by their students, staff, and industry partners. When it came time to upgrade the legacy controls, a joint project was initiated with NCSU, CESMII (The Smart Manufacturing Institute), and Avid Solutions.

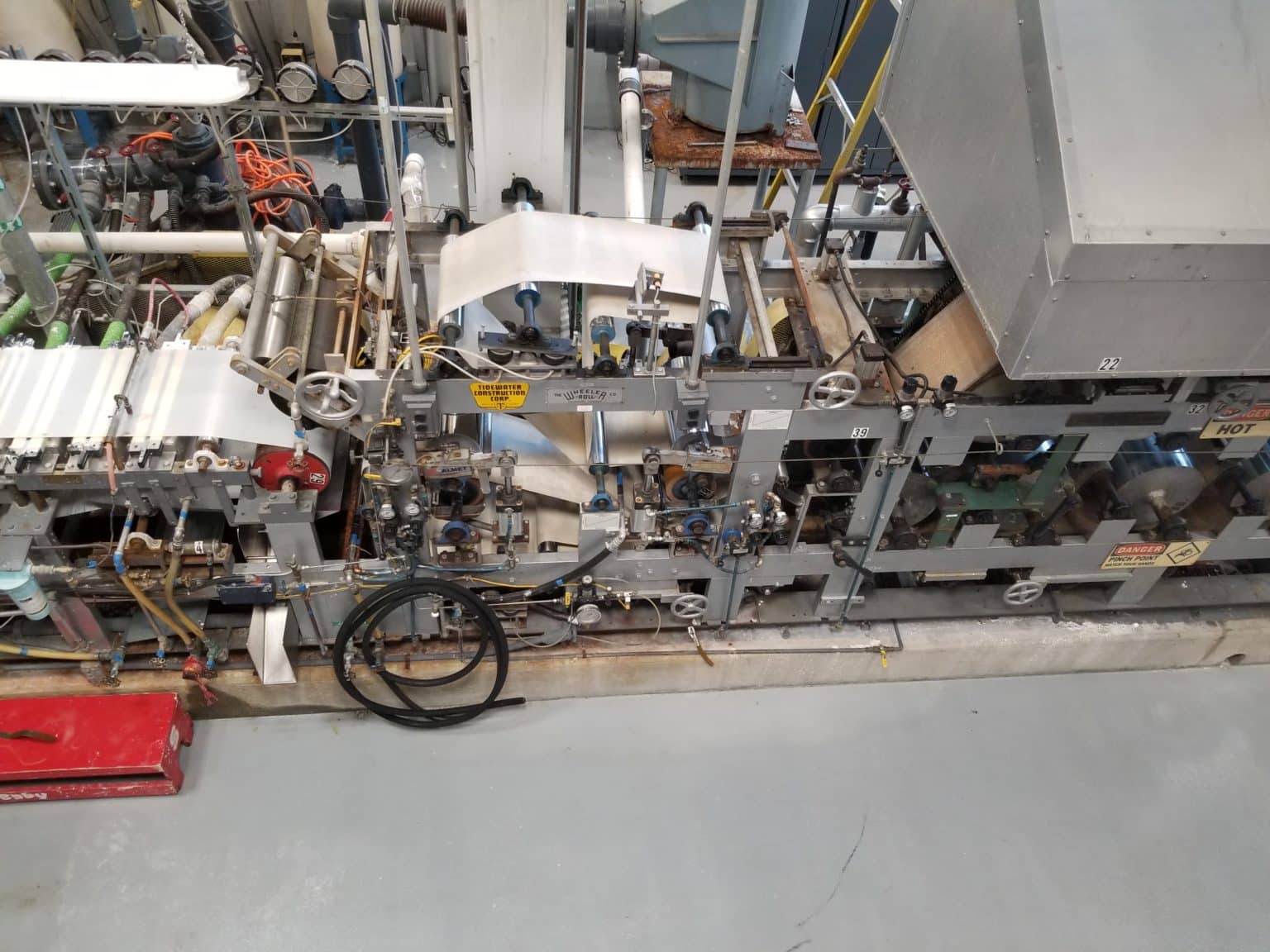

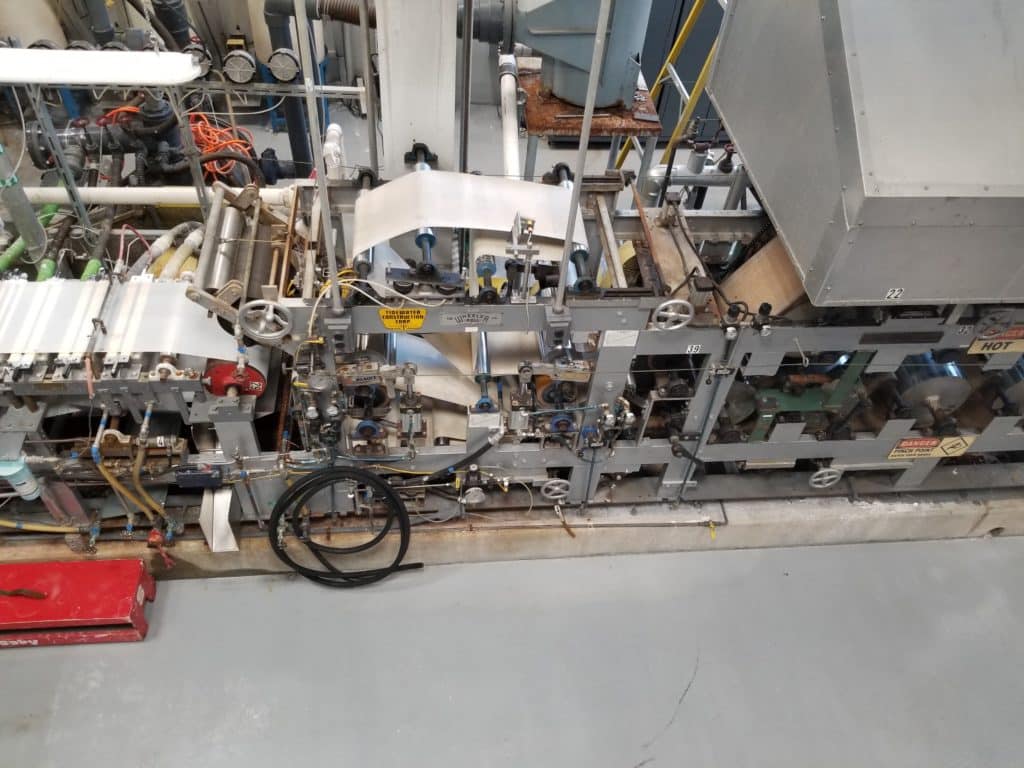

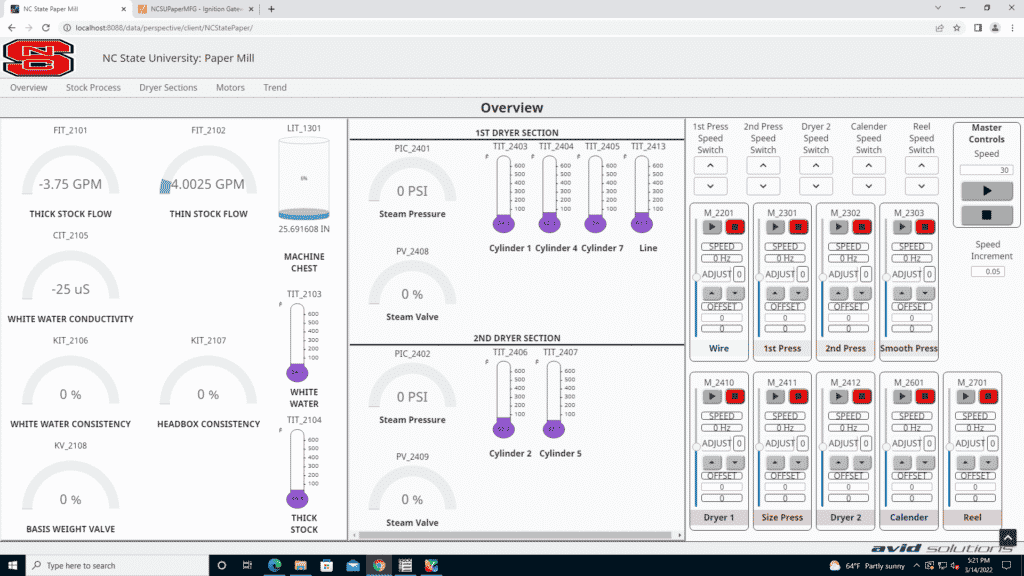

Known as the Paper Pilot Plant, the production line includes multiple pre-stock tanks, four presses, two dryers, one calendar, one scanner, and one reel section, able to produce about 70 linear feet of 3-foot-wide paper per minute. NCSU personnel involved with the production line include three professors, one maintenance person, and many graduate and undergraduate students. Legacy controls had provided basic functionality for many years, but an upgrade was needed to improve performance and provide remote connectivity.

Avid was engaged to upgrade the old controls and HMI, and to assist with connecting data to a new cloud-based system developed by CESMII. CESMII is developing an industrial standard for organization of cloud data, and this project was an ideal test bed.

The upgrade project provided an opportunity to improve the control fundamentals, while providing more data and functionality to interact with the CESMII system. NCSU also wanted the ability to use mobile devices, like tablets and phones, to monitor the control system. An additional benefit is that the VFDs would be migrated from hardwired I/O to modern EtherNet/IP connectivity, providing advanced operational and data transfer capabilities.

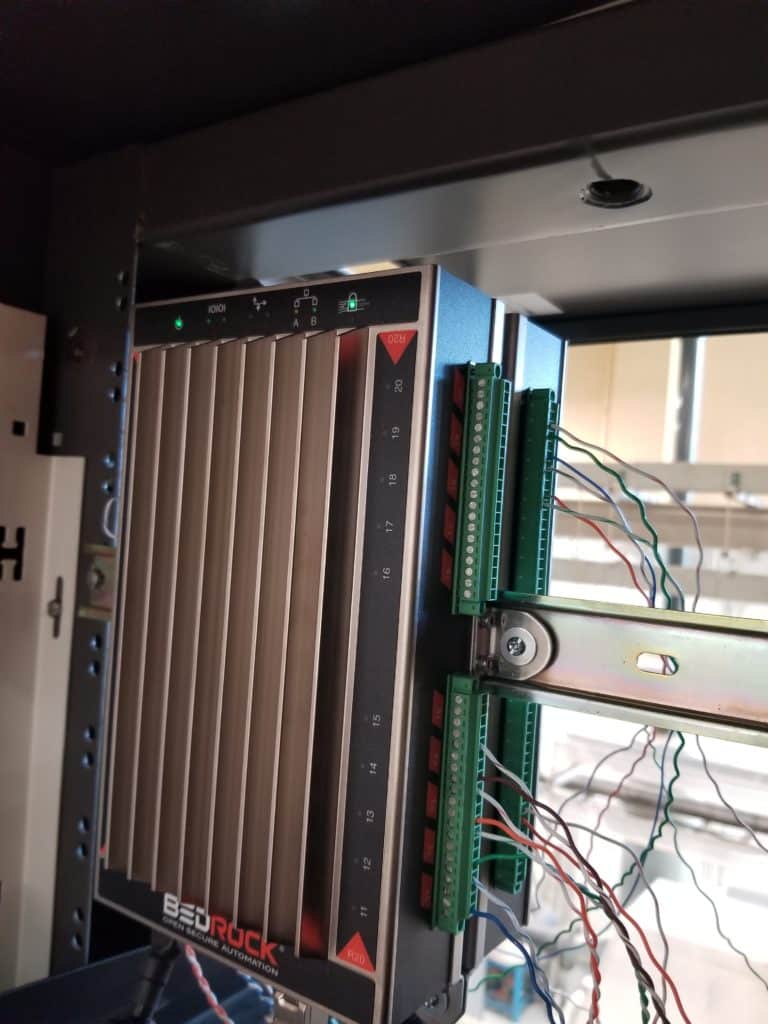

A pair of Bedrock Automation OSA Remote Controllers and PowerFlex 753 VFDs were selected for the hardware, while Inductive Automation Ignition 8.0 Perspective and OSIsoft PI were integrated for the HMI/SCADA and historian roles. CESMII provided a PI data connector for pulling data into their cloud platform.

Avid installed all software on a new quad monitor workstation supplied by NCSU. The Ignition platform drives the multiple displays, and its web server functionality supports mobile device connections for both controlling and viewing the system. Avid took advantage of function block objects in the Bedrock library to efficiently create user defined data types in Ignition, simplifying data mapping. Bedrock allows for both traditional ladder logic and more modern function block languages to be used on one platform, providing needed programming flexibility. The resulting system is aligned with traditional industrial standards for control and visualization.

Adapting to projects of all types

Avid’s team of process experts and technical innovators is well versed in a wide range of industrial automation, visualization, and connectivity technologies. Most projects are executed for large manufacturers, but this project took the team back to school—literally. Regardless of the automation or integration need, Avid is ready to partner with clients of all types to safely and efficiently build or upgrade their systems.

To learn more about Avid’s capabilities to solve process control, automation, and smart manufacturing challenges, contact us here!