Six Big Benefits of the Inflation Reduction Act.

Passage of the Inflation Reduction Act (IRA) will provide significant investments in technologies and industries working to reduce fossil fuel usage, lowering carbon emission, while reducing cost to consumers. Check out the following (page advance is at the bottom of the frame!)

Hydrogen Insights 2022 – The Pipeline Grows!

The pipeline of hydrogen projects is continuing to grow, but actual deployment is lagging.680 large-scale project proposals worth USD 240 billion have been put forward, but only about10% (USD 22 billion) have reached final investment decision (FID). While Europe leads in proposedinvestments (~30%), China is slightly ahead on actual deployment of electrolyzers (200 MW), whileJapan […]

Retaining Value – Key Aspect of the Circular Economy.

Contrary to popular thinking in various companies, the circular economy isn’t the latest sustainability fad and shouldn’t be thought of as a recycling or green program. It requires top-down management and change across a company, including reevaluating product design, business models, and the supply chain. what the circular economy is and how companies create loops throughout […]

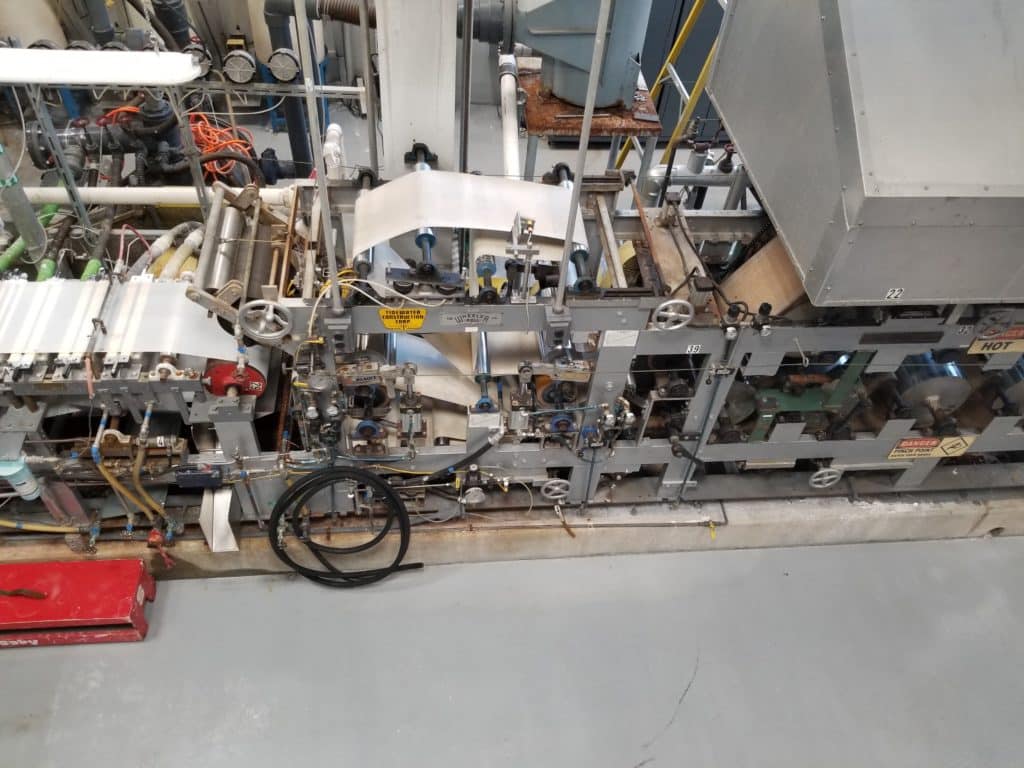

Avid Solutions Upgrades a Pilot Paper Plant

At North Carolina State University, a paper production pilot plant is operated for research and education relating to the pulp and paper industry. This represents a unique real-world opportunity for testing and investigation by their students, staff, and industry partners. When it came time to upgrade the legacy controls, a joint project was initiated with […]

DCOM Security Update!

Upcoming patches being released by Microsoft will impact automation systems using software products like Factory Talk View, Wonderware and OPC servers like Kepware. Microsoft’s Distributed Control Object Model (DCOM), provided on Windows based operating systems, is used for the communication between software components (applications) on a local device and remotely between software components on other […]

Capturing the True Value of Industry 4.0

In the past five years, a select group of companies have started pulling ahead in their efforts to implement Industry 4.0 across their manufacturing networks. Leading manufacturers are now realizing significant value from data and analytics, AI, and machine learning (ML). However, a large majority remain stuck in pilot purgatory, struggling to capture the full potential […]

Flammability in a Biofuel Process? Assuring Safety is a Must!

For every industrial process, especially when working with combustible gases, human health and safety is the top priority. For a startup biofuel processor creating renewable fuels, this necessitated addressing the risks associated with flammable vapor releases from its fermentation processes. The processer needed to implement a system to monitor combustibility of the gases in its […]

Modernizing a Biofuels Process? Avid Met the Challenge!

One of the world’s leading green processing companies transforms plant sugars into biofuels for products in the food, home, personal care, chemical, and fuels industries. When they acquired an idled manufacturing plant, a complete upgrade was required to operate in accordance with Good Manufacturing Practice (GMP) standards. Antiquated control system hardware, outdated control applications, extensive […]

Avid to the Rescue! Emergency Support Restores Critical Data Link.

The hardware and software for our mobile devices, PCs, and other consumer electronics are constantly updated—often automatically. However, many industrial automation end users operate specialized systems that can remain in service for years or decades without maintenance. When these systems fail, and local support is not available, the resulting unplanned downtime results in irretrievable lost […]

Navigating to NetZero: Investment in Innovation.

An excellent article by McKinsey, and a must read for anyone interested it where investment in technologies to decarbonize the energy supply chain, and promote green production of foods and other manufactured goods are being made. The Avid team is doing its part in the drive to Net Zero by developing standards that Innovate, Optimize, […]